The threshold range of Vth is limited to a certain range (3%), so that the current difference between the two MOSFETs is small:

The value of Vth1 is low, so ID1 is slightly higher than ID2.

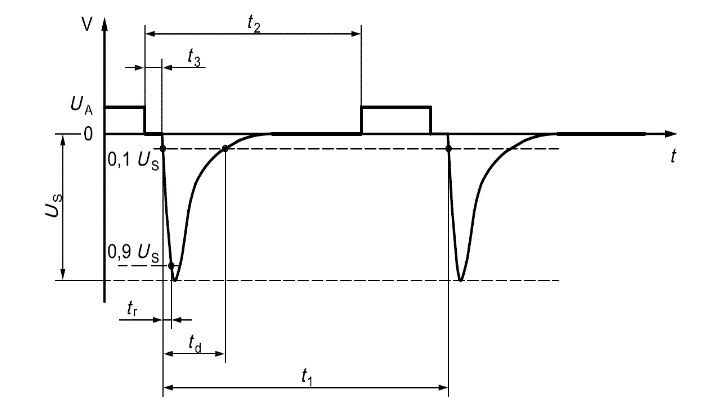

In this case (Case 2), the linear mode robustness of the power switch is tested with a high current, and the pulse time lasts for a few milliseconds.

In both cases, the power MOSFETs are able to withstand linear mode operating conditions and are within the theoretical safe working area (SOA) to prevent any thermal runaway of the device.

2.Off state

When switched off, the power MOSFETs must be subjected to enormous energy discharge stress. In fact, on the harness connecting the main battery to the end application control board, the parasitic stray inductance produces a high impedance, causing a powerful discharge event in the distribution system.

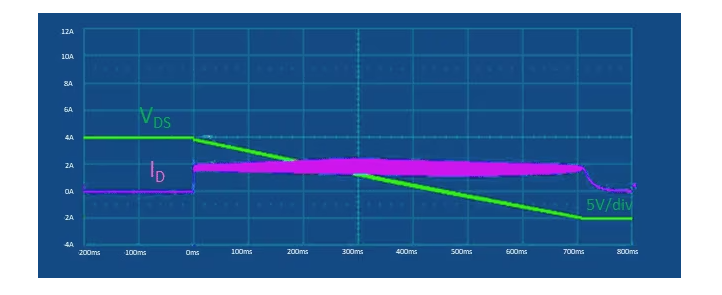

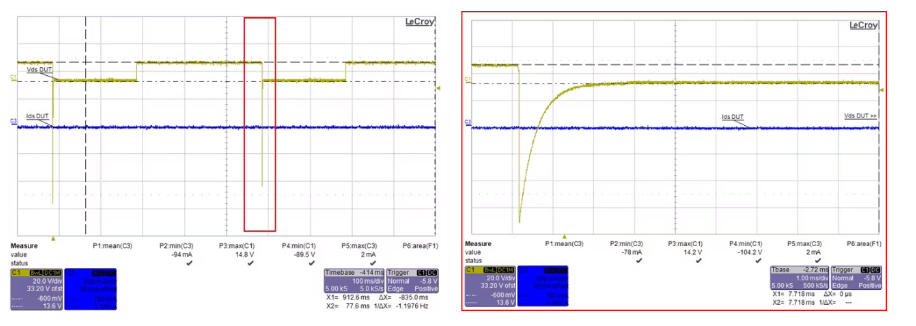

In the case of ECU, this energy release can be treated as a single avalanche event when the MOSFET is turned off, or an active clamping circuit can be used to force the MOSFET back to linear operating mode. TL325N4LF8AG can maintain normal operation in 40A avalanche breakdown test, as shown in Figure 5:

Figure 5. Measured waveform of STL325N4LF8AG for a single avalanche event at shutdown

The device has strong energy handling performance in the off state.

According to ISO 7637-2

For 12V/24V automotive power supply systems, eFuse electronic safety switch tubes must meet the main requirements of the ISO 7637-2 international standard and be able to withstand the violent high and low power transient events generated on the power supply rail, in some cases with high dv/dt voltage rise rates.

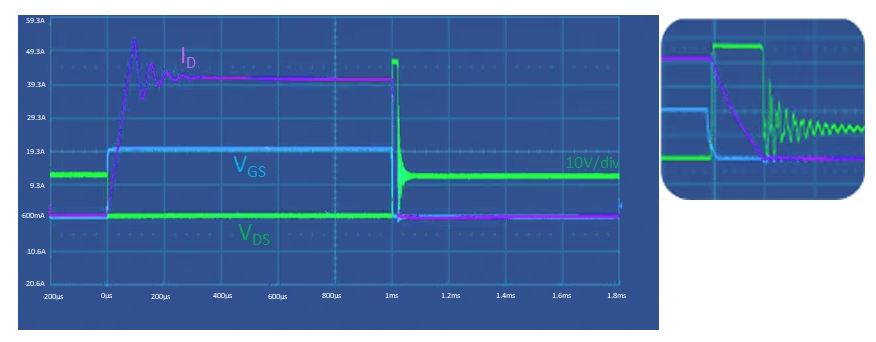

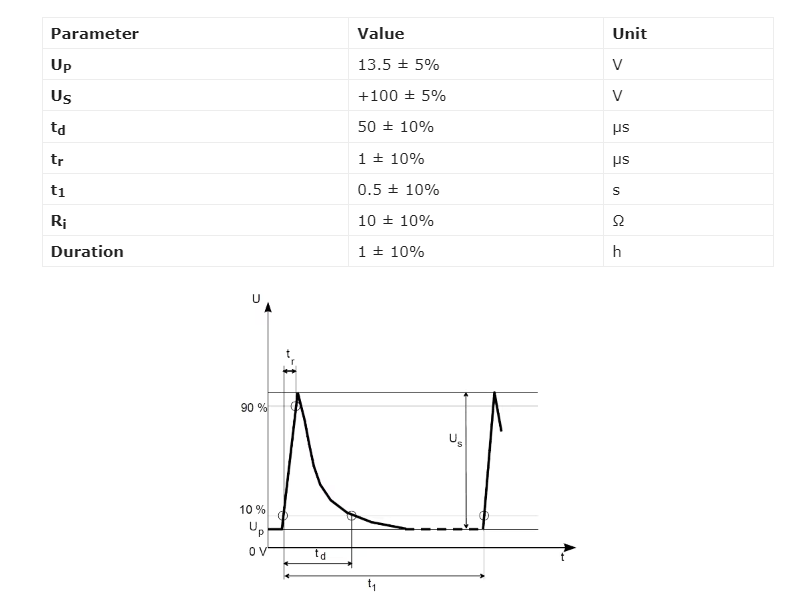

1.ISO 7637-2 Pulse 1 standard

The Pulse 1 standard describes the negative voltage transients observed on electronic devices in parallel with inductive loads when the power connection is disconnected, as shown in Figure 6.

Figure 6. Voltage transient waveforms and parameters tested by ISO 7637-2 Pulse 1

The test results shown in Figure 7 demonstrate that the STL325N4LF8AG meets the requirements of ISO 7637-2 Pulse 1:

Figure 7. Measurement waveform of the STL325N4LF8AG's ISO 7637-2 Pulse 1 test

The experimental data show that the STL325N4LF8AG has passed the ISO 7637-2 pulse 1 test without any failure or reduction of main rated parameters.

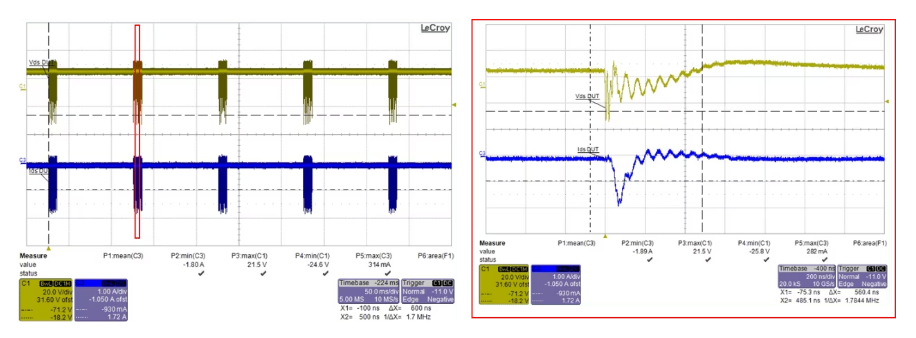

2.ISO 7637-2 Pulse 2° standard

The Pulse 2a standard describes positive voltage spikes that may occur when the circuit current in parallel with the electronic device under test is interrupted, as shown in Figure 8:

Figure 8. Voltage transient waveforms and parameters of the STL325N4LF8AG's ISO 7637-2 Pulse 2a test

The test results shown in Figure 9 demonstrate that the STL325N4LF8AG meets the requirements of ISO 7637-2 Pulse 2a:

Figure 9. Measurement waveform of the STL325N4LF8AG's ISO 7637-2 Pulse 2a test

The experimental data show that the STL325N4LF8AG has passed the ISO 7637-2 pulse 2a test without any failure or reduction of main rated parameters.

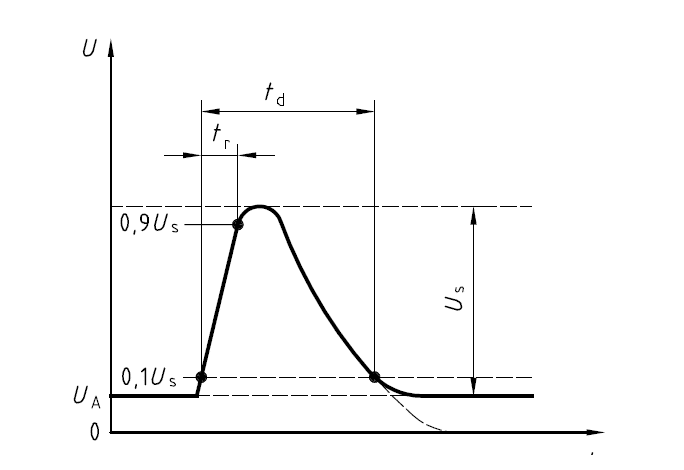

3.ISO 7637-2 Pulses 3a and 3b standards

Pulses 3a and 3b define the negative voltage spikes that may occur during the switching process due to the distributed capacitance and inductance of the harness, as shown in Figures 11 and 12:

Figure 10. Voltage transients for ISO 7637-2 pulse 3a test.

Figure 11. Voltage transients for ISO 7637-2 pulse 3b test

Table 2 lists the measured values of each parameter:

Table 2. Voltage transient parameters tested by ISO 7637-2 pulses 3a and 3b

Figure 12 and 13 are the experimental data related to the ISO 7637-2 pulse 3a and pulse 3b tests of the STL325N4LF8AG:

Figure 12. Measurement waveform of the STL325N4LF8AG's ISO 7637-2 pulse 3a test

Figure 13. Measurement waveform of the STL325N4LF8AG's ISO 7637-2 pulse 3b test

The pulse 3a and 3b test results of the STL325N4LF8AG are satisfactory.

4.ISO 7637-2 Pulses 5a and 5b (load drops)

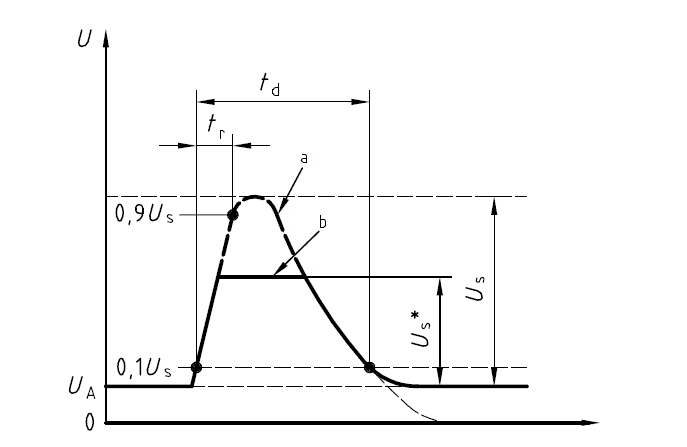

Pulses 5a and 5b are simulated tests of load drop transients. Load drop refers to the situation where the discharge battery is disconnected while the other loads are still connected to the alternator during the period when the alternator is generating charging current, as shown in Figures 14 and 15:

Figure 14. Voltage transients for ISO 7637-2 pulse 5a test

Figure 15. Voltage transients for ISO 7637-2 pulse 5b test

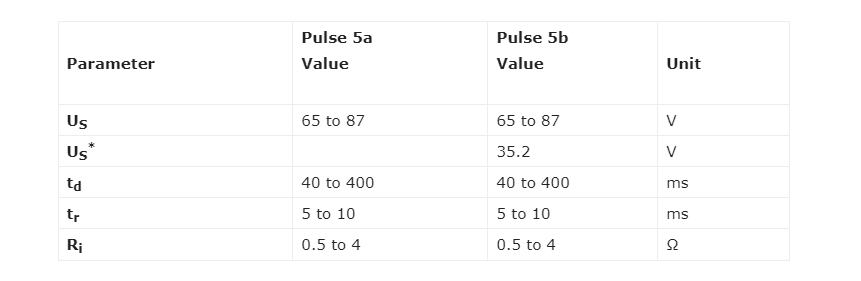

Table 3 lists the test parameter values of the 12V system:

Table 3. Voltage transient parameters tested by ISO 7637-2 pulses 5a and 5b

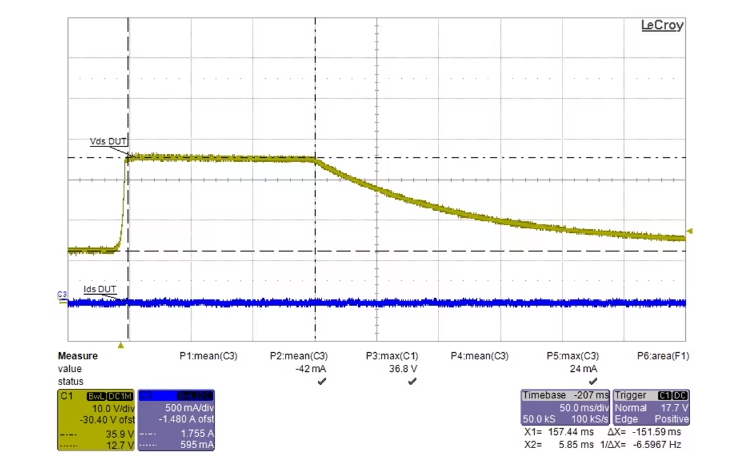

Figures 17 and 18 show the measurement waveforms for the STL325N4LF8AG's ISO 7637-2 pulse 5a and pulse 5b tests:

Figure 16. Measurement waveform of the STL325N4LF8AG's ISO 7637-2 pulse 5a test

Figure 17. Measurement waveform of the STL325N4LF8AG's ISO 7637-2 pulse 5b test

Therefore, the STL325N4LF8AG can also provide load drop protection for the system

Conclusion

The STL325N4LF8AG uses ST's newly developed STripFET F8 manufacturing technology and is specifically designed to withstand all relevant voltage stress conditions for eFuse electronic insurance applications, both in power off and on states. In addition, the MOSFET has also passed the international standard ISO 7637-2 12V/24V automotive battery system on-transient test. The best-in-class performance makes the STL325N4LF8AG ideal for designing safer power distribution systems in harsh automotive applications.

Heisener Electronic is a famous international One Stop Purchasing Service Provider of Electronic Components. Based on the concept of Customer-orientation and Innovation, a good process control system, professional management team, advanced inventory management technology, we can provide one-stop electronic component supporting services that Heisener is the preferred partner for all the enterprises and research institutions.