The current satellite communications infrastructure is unable to meet the relentless worldwide need for dependable, high-speed broadband access. The existence of this gap is driving the swift creation, advancement and implementation of satellite constellations for low-Earth-orbit (LEO) and medium-Earth-orbit (MEO) communications.

These satellites have significantly transformed connection and data transmission by simplifying worldwide internet access and enabling real-time Earth observation. Nevertheless, in the middle of their capacity for profound change, they face a substantial obstacle: power management.

In an interview with Power Electronics News, Matt Renola, Senior Director for the Vicor Aerospace and Defense business unit, discussed the power delivery network challenges this new class of smaller but more powerful satellites pose with their advanced, higher-power network communications processors and limited space for power.

Challenges of low-orbit satellites

In contrast to conventional geostationary satellites, which require anti-radiation components and are powered by expanding solar arrays, low-orbit/low-Earth orbit satellites operate within orbit, within the Van Allen Belt, which is characterized by regular fluctuations in solar exposure. This requires radiation-resistant power electronics capable of achieving high efficiency in power conversion.

Additionally, there are new difficulties in distributing electricity due to the tendency toward downsizing in satellite design. To make the most of the space available, engineers need to design systems that are both compact and robust; that is, able to control the flow of power while keeping weight and volume to a minimum.

Satellites also face challenges in deflecting high-energy particles due to the lack of Earth’s magnetic field. In addition, the absence of Earth’s air barrier renders space systems susceptible to heightened levels of wave and particle radiation, which have the potential to induce component malfunctions and potentially jeopardize the integrity of the system. Another challenge arises from heat dissipation, as the process of convection cooling is not effective in space, therefore restricting the transfer of heat by conduction to a radiating surface.

Particle radiation causes physical harm, namely to the lattices of semiconductor crystals, which can be either permanent or cumulative. Temporary disturbances can be observed in which electrons are transported into depletion zones, resulting in the conduction of a non-conducting region. Malfunctions can occur when positive ions substitute doping atoms in a crystal matrix, leading to the occurrence of conductive behavior in a semiconductor where it is not intended, ultimately causing irreversible harm to equipment.

Vicor’s power solutions

The range of Vicor radiation-tolerant power modules is designed to provide low noise, high power and current density, reliability and scalability needed to supply power to LEO and MEO satellites in a compact form factor. The solution relies not only on the scalable power modules, but also on proprietary power architectures and topologies to unlock top performance.

“We’ve utilized our proprietary factorized power architecture (FPA) for designing a radiation-tolerant power delivery network for LEO and MEO satellites, where space savings is obviously critical,” said Renola.

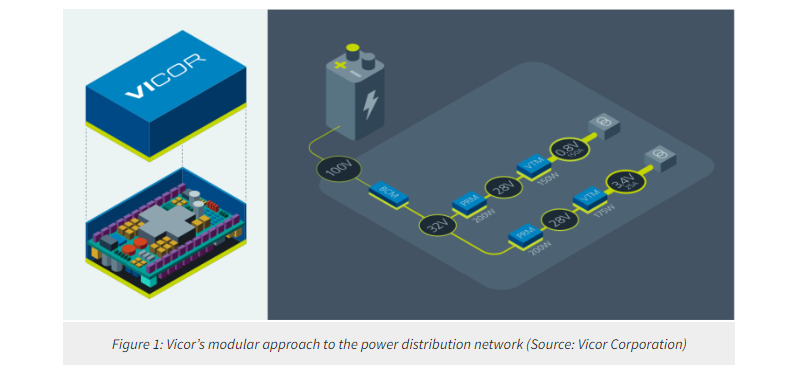

The Vicor power delivery network (PDN) employs internally redundant power modules that achieve the best power and current density in the industry. Furthermore, its architecture and implementation are very flexible and scalable (Figure 1).

Vicor’s patented radiation-tolerant power module solutions have been chosen for the Boeing O3b program (O3b stands for “other 3 billion people”) that, taking a modular approach for LEO satellites, aims to extend access to reliable, high-speed broadband connectivity to the four corners of the world, especially to those people with limited or no access to high-speed internet.

One significant obstacle encountered in the construction of LEO satellites, such as O3b, pertains to the provision of sufficient power to sustain power-intensive modern communication circuits while minimizing the dimensions and mass of the power distribution network. The power solution must also exhibit the flexibility and scalability to effectively handle any unanticipated design alterations or revisions in subsequent iterations.

“The latest submicron application-specific integrated circuits (ASICs) or field-programmable gate arrays (FPGAs) require very high currents at low voltages. The Vicor Factorized Power Architecture (FPA™) of a three-module solution (BCM®, PRM™ and VTM™) is very compact and flexible. A key advantage to using these modules is that they factorize the PDN and don’t need to be located near each other in the design. The BCM can be located near the power source, and the VTM which has very low noise can be placed as close as possible to the ASIC or FPGA to reduce I2R loss,” said Renola.

The Vicor power source to the point-of-load (PoL) solution includes the following power modules:

● BCM3423, a 100V nominal, 300 watt K = 1/3 bus converter in a 34mm x 23mm package

● PRM2919, a 33V nominal 200 watt buck-boost regulator in a 29mm x 19mm package

● Two VTM2919 current multipliers, with a voltage transformation of K = 1/32 with an output of 0.8V at 150A and a K = 1/8 with an output of 3.3V at 50 amps.

Alternative satellite PDNs that use 28V power delivery can use the Vicor 28VIN (22 – 40V) FPA solution.

The radiation- and fault-tolerant modular solution is capable of powering low-voltage ASICs and FPGA’s up to 300 watts from a 100V nominal power source, requiring minimal external components with low-noise operation. All of the modules are available in the Vicor high-density ChiP™ package with –30 to 125°C operating temperature.

“It is the same architecture that Vicor uses with its data center and AI processor customers, getting high current to the PoL and significantly reducing motherboard I2R power losses by being closer to the processor,” said Renola.

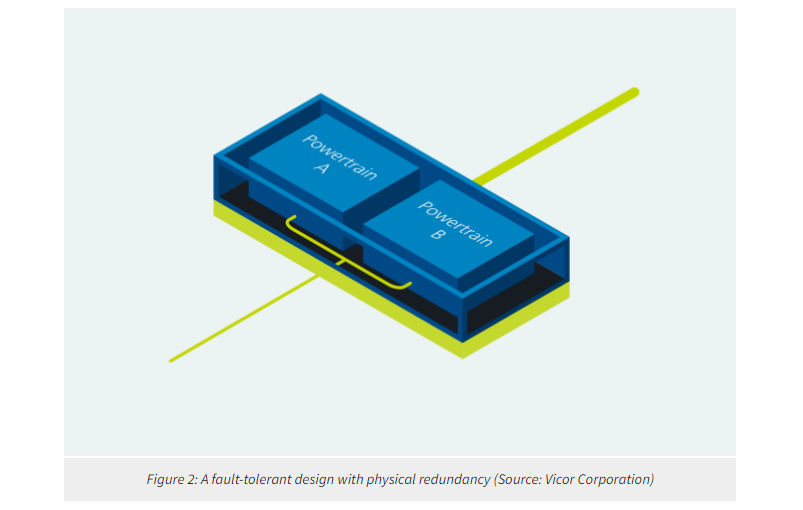

In space applications, physical redundancy is also important to ensure that, if one system fails, another can take over. The redundant architecture within each Vicor module ensures immunity to single-event upsets. This is achieved by housing two identical and parallel powertrains with fault-tolerant control ICs in a single, high-density SM-ChiP package (Figure 2).

In the case of a single event causing an upset in one powertrain, its protective circuits initiate a power-off reset. During the period of reset, the redundant powertrain assumes the responsibility of carrying the entire load, and subsequent to the reset, both powertrains resume parallel operation.

“We have designed and built physical redundancy within our converters so that we have fault-tolerance solutions,” Renola said.

Low noise, zero-voltage and zero-current switching (ZVS & ZCS)

High power density and low noise are essential requirements for advanced communication satellites. To mitigate noise, the implementation of switching modes like soft switching, as opposed to hard-switched power converters, can effectively decrease the susceptibility of a system to parasitic effects like ringing. These effects have the potential to elevate voltage stress on the switching components. The zero-voltage-switching (ZVS) technique is an illustrative instance of soft switching, as it enhances conversion efficiency across various power topologies.

The utilization of Vicor’s soft-switching, high-frequency, zero-current-switching (ZCS)/ZVS power stages effectively mitigates the noise floor within the power system, thereby minimizing the need for filtering. This in turn enhances signal integrity and overall system performance while ensuring a high level of reliability. The ZVS buck-boost architecture is employed by Vicor for the PRM, while the BCM and VTM utilize ZVS and ZCS sine-amplitude converters.

About US