Driven by high-speed digital technology, the rapid development of various complex medical systems has also made many services in the medical field significantly improve in performance, accuracy and efficiency. Medical imaging systems play a vital role in early detection and diagnosis in various medical fields such as orthopedics, obstetrics, neurology, cardiology, etc. Surgical robots, hospital-specific robots, and telemedicine systems can help healthcare practitioners detect and diagnose conditions, improve the quality of care, and even extend patients' lives. All of the above functions need to be achieved through high-speed digital signals, which means that the signal integrity of the entire system is extremely important.

Software innovation has led to more high-speed digital hardware

Intelligent automation, driven by software, provides major value to these complex healthcare systems. Software in medical devices can process and remove noise from images, generate 3D images, and train and use neural networks to segment and classify images. For example, magnetic resonance imaging (MRI) uses software algorithms that recognize and highlight abnormalities such as tumors or fractures to help radiologists make a diagnosis.

With the increasing use of software, these complex medical systems can be deployed to increasingly challenging applications. In these applications, excellent reliability, speed and low latency are critical to keeping customers safe. This means that the digital hardware performance of the device must be improved in order to achieve faster data detection, data acquisition and signal processing, which requires more and faster digital processors and image coloring processors, faster memory, faster clock rates, higher frame rates, faster interconnections, and advanced digital logic technology and multilevel signaling schemes. Includes PAM4, PAM8, PAM16, and non-return-to-zero (NRZ) logic. In addition, growing cybersecurity threats in recent years, as well as stringent regulatory requirements to protect patient privacy, are driving the industry to adopt digital hardware for tasks such as data obfuscation, encryption, and validity checking.

The increase in high-speed digital hardware has created testing challenges

The extensive use of high-speed digital hardware presents complex testing challenges in the following ways. Low bit error rates can affect the safety of patients and the reliability of medical devices, so how to identify low bit error rates is critical. The increase in the amount of data means that even a very low bit error rate can lead to many error codes, as error codes accumulate rapidly over time. Medical diagnosis depends to a large extent on the accuracy of data transmission between the various components of the system. For example, in imaging systems used for diagnosis, such as MRI or CT scanners, errors in data transmission or processing can lead to problems such as distorted images generated from large amounts of digital data, potentially resulting in misdiagnosis.

In high-speed digital hardware, the increase in component density on the PCB board means that the wiring space is reduced, which will inevitably lead to an increase in the number of board layers, and the difficulty of testing will also increase. The more compact the package design of components, the higher the power density, which may cause local heating of the circuit board. However, medical devices require sophisticated temperature control to ensure device functionality and patient safety, and inadequate thermal management can lead to overheating, component failure, or performance degradation due to temperature increases.

High-speed digital hardware also presents some additional testing challenges. As the clock rate and data transmission rate increase, the tolerance of the eye image to signal noise and jitter becomes smaller. Multilayer boards with more through-holes require a complex manufacturing process to improve signal integrity. In addition, the increase in component density requires a narrower path width, which increases the possibility of accidental openings compared to wider designs. Because the space of the wiring is compressed, the possibility of crosstalk is greater, because the magnetic field may generate induced voltage throughout the circuit, and the electric field may form parasitic capacitance.

Simulation is essential before the device is manufactured

In order to meet the testing challenges of high-speed digital hardware and reduce risk in medical systems, it is critical to simulate the operation of the board before the design is delivered to production. While simulation may not detect all potential problems, it can play an important role in identifying as many as possible. There are several advantages to simulating devices prior to manufacturing. It helps improve the actual performance of the board and reduces the number of iterations of the hardware prototype design, thus saving time and cost. Simulation also speeds up prototype development and minimizes unplanned modifications, testing, and documentation of the board. Simulation can also eliminate false signals that could be mistaken for faults, allowing for rapid advancement of firmware and software testing. In addition, resolving these issues is crucial for advanced digital logic protocols such as PAM4, PAM8, PAM16, and NRZ, which have relatively low tolerance for signal quality fluctuations.

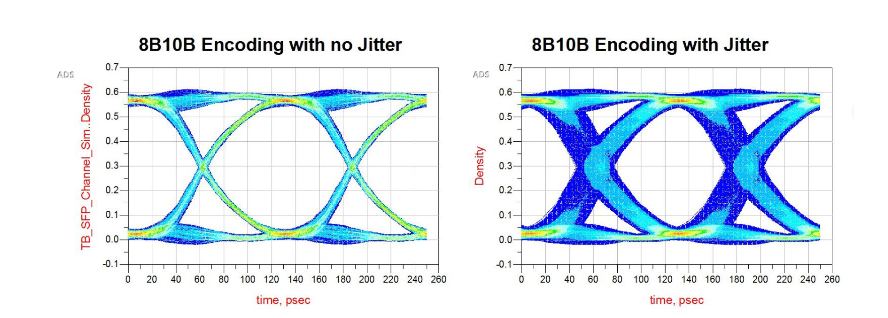

Signal integrity analysis of complex high-speed PCB boards can be performed using simulation software. Figure 1 shows an example of using simulation software to analyze the effect of jitter on the eye map. The loss and coupling of signal and power networks can be characterized simultaneously by using simulation software. The simulation software also helps users extract and seamlessly transfer accurate electromagnetic (EM) models for use in ADS transient and channel simulators. Users can also save time by quickly checking the line impedance before EM extraction with simulation software. This reduces the risk of errors in patients' private data or images.

Figure 1: Simulation software is used to analyze the effect of jitter on the eye map.

It is of great significance to measure signal integrity after PCBA proofing

Even though engineers use signal simulation software, they are extremely careful to complete the wiring and printed circuit board assembly (PCBA) proofing processing, but considering many reasons, engineers still need to use oscilloscopes to measure the signal integrity of the circuit board after processing and manufacturing. Although the technical specifications and specifications are followed, there are still some changes within the components, and the signal integrity analysis software cannot fully explain the reasons. In addition, components usually have inherent parasitic analog characteristics such as impedance, capacitance and inductance, which have no corresponding technical indicators.

The mounting process of surface mount (SMT) devices is subject to a variety of changes that can cause the components on the pad to be off-center. In addition, the steel mesh process may not consistently form a perfect solder block, and the size of the solder buildup will shrink under continuous use. Over time, the chemical composition and characteristics of the solder may change slightly, affecting the solder joint bond between the brazing pad and the SMT device. In addition, the normal fluctuation in the reflow furnace will affect the reflow characteristics of the solder. Even if the electrical connection is established at the welding point, the welding firmness may not be enough, and there are phenomena such as missing solder pins of the wing parts, on-board passive SMT resistors, and pillow effect of ball grid array (BGA) joints. Using an oscilloscope after manufacturing is complete helps to fully evaluate and resolve signal integrity issues that may result from these factors.

The oscilloscope allows engineers to understand the intricate interactions in complex designs. As shown in Figure 2, the oscilloscope can measure up to eight channels simultaneously to quickly check whether the PCBA produced by processing has signal integrity problems. Engineers can use oscilloscopes for logic analysis, real-time spectrum analysis (RTSA), serial protocol analysis, waveform generation, frequency response, and phase noise testing. Due to the high demand for data communication speed, healthcare systems use high data transfer rates and parallel data channels with small spacing.

As a result, electromagnetic coupling (i.e., crosstalk) increases. In addition, power supplies can cause disturbances such as noise and jitter to the data channels they drive; In turn, data-dependent noise can also have an impact on the power supply, such as synchronous switching noise (SSN), which can cause ground rebound. The oscilloscope can detect and quantify crosstalk, determine which main interference sources cause crosstalk, and can also detect and diagnose jitter, vertical noise and phase noise.

Conclusion

High-speed digital technologies enable a range of advanced capabilities in areas such as imaging, diagnostics, telemedicine, personalized medicine and patient care, revolutionizing complex healthcare systems and leading to more efficient, effective and patient-centered care. Building a high-speed digital health system is always a challenge. As data transfer rates and image resolution increase, and edge computing is increasingly embedded in systems, engineers are increasingly challenged to maintain signal integrity commensurate with their applications. By using simulation software before PCB fabrication and oscilloscopes with powerful software capabilities after fabrication, products with the required efficacy and safety can be brought to market to reduce the risk to patients.

About US

Heisener Electronic is a famous international One Stop Purchasing Service Provider of Electronic Components. Based on the concept of Customer-orientation and Innovation, a good process control system, professional management team, advanced inventory management technology, we can provide one-stop electronic component supporting services that Heisener is the preferred partner for all the enterprises and research institutions.